Launched in 2014, Biofabricate has been at the forefront of a material revolution, built by a founding team with expertise in the design industries and biotech start-ups. Suzanne Lee, CEO and founder, has been pioneering microbial fashion materials since 2003 with Biocouture and is a Launch Material Innovator—an initiative sponsored by NASA, Nike, the U.S. Department of State, and the U.S. Agency for International Development. Chief Design Officer Dr. Amy Congdon has worked in biofabrication for over a decade, previously acting as Associate Director of Materials Design at biotech company Modern Meadow. A consultancy, design agency, and educational platform, Biofabricate hopes to drive forward a more sustainable material world, innovation by innovation. “Biofabricate is all about our material world built with biology. That's what I get excited about: when biology can do something that chemistry can't,” Lee comments.

Its annual summit gathers both established and emerging entrepreneurs of the genre. The 2024 edition took place over three days at the Fondation Fiminco in Paris, an ex-pharmaceutical fermentation factory. Sponsors included Kering, MycoWorks, and Parley for the Oceans. Over 50 exhibitors showcased their offerings spanning apparel, personal care, and packaging over three floors, from OurCarbon to LanzaTech, while onstage panel discussions included Augustinus Bader, GANNI, and PANGAIA.

This year’s edition was the largest summit yet, with beauty proving to be a category of increased interest. “Biofabricate actually started as an event that was very much focused on biomaterials and biomaterials for consumer products, but super broad. We decided, if we're going to do Biofabricate in Paris, we should definitely expand the beauty program alongside the materials,” Lee tells BeautyMatter of the genre. “There are some things that the beauty industry seems to want to replace; a drop-in for perhaps a petrochemical-derived ingredient. Then there is also a desire to find new functional ingredients that deliver real results. We're learning all the opportunities for biology and biotechnology to step in and play a role in the future.”

Microplastics have been a key talking point of those changes, with a 2021 study that found traces of microplastics in human placenta further pushing a fast pipeline for alternative solutions. The EU announced the ban of microplastics in cosmetics in 2023, but that’s not all that can be done. It’s not just little beads in scrubs but other petrochemical- or animal-derived materials as well as those that are currently produced in agriculturally unsustainable ways that could receive a biotech upgrade. “One of the things that struck me when I was interviewing the innovators, trying to understand what it is they are producing and why does this matter, is a conversation with the CEO of Bioweg who was talking about the high percentage of plastics that are in skincare. Obviously we've known about these sort of microbeads for a while, but all the other ingredients that are petrochemical- and plastic-derived that we're absorbing through skin, that was a big opportunity space,” Lee notes. “On the other side, there's such a beautiful, holistic story there around certain organisms and what they can make for us that we're only just beginning to embrace. Jesse Adler’s company Pitri is doing fungal [cosmetic] colors, which is a beautiful project. I could imagine that category exploding as we learn more and more about fungi derived ingredients.”

A big portion of that equation is funding, and it’s at summits like Biofabricate where interested backers can find the industry’s next masterminds. Lee admits the fundraising environment over the last 24 months has been challenging, as is finding the right partners to work with in scaling innovation. “Especially if you're doing something like fermentation, I think we could be challenged around the capacity for access to facilities to brew more of the ingredients. If you think about it, many of those large-scale facilities are already given over to customers who have a certain priority,” she adds. Here is where the right backing can make all the difference. Recent investments from industry giants like L’Oréal and Symrise in the category are undoubtedly steps in the right direction. At the summit, Coty and LanzaTech’s partnership, as well as K18, which was recently acquired by Unilever, were on display and are testaments to the power of industry forces coming together.

When asked how the beauty industry can better support biotech start-ups, Lee comments, “It’s about a willingness to go on a journey with an innovator and support them through, not just coming in at the end with an M&A mindset of buying the company. If we want to see more innovators working in the space, you need to create an environment that is hungry for innovation and there to really support from the beginning.”

Lee hopes that the next wave of innovators will be able to take the insights shared from K18’s Suveen Sahib and Augustinus Bader’s Charles Rosier onstage at the event as an opportunity to strategize on their entryway into the market, be it in a B2B or D2C fashion. Equally, it’s an opportunity for larger corporations to get up close and personal with the latest forward-thinking scientific prospects. “Biofabricate definitely wants to bring that to the fore, speak to some of those founders who've got wildly successful products based on biotechnology; having a design lab showcasing young and experimental individiuals and then also showcasing big biotech beauty success stories, so people can see the landscape and inspire those big brands as well. Who is the next Augustinus Bader? Maybe it's someone in that room,” she says.

This year’s event was certainly a roaring success in bringing the beauty, fashion, and packaging industries together for a galvanizing meeting of minds and biotech possibilities, with plenty of ripple effects for the years that lie ahead.

To celebrate, BeautyMatter rounded up the top innovators, big and small, changing the future of beauty packaging and ingredients.

Insempra

The mastermind behind Insempra (formerly Origin.bio), described by Forbes as “one of the most proactive minds in our industry” is Jens Klein, the former CEO of AMSilk, a leading developer of bioengineered spider silk materials for application in jetliners and watch straps. With Insempra, he desired to create an enterprise with a market-driven approach that focuses on offering innovative solutions at a quick-to-market speed. In the world of biotechnology, where cutting-edge concepts can often take years to develop and bring to market, this momentum is incredibly vital.

Fueled by a $15 million seed funding round led by EQT Ventures with participation from BlueYard Capital, Inventures, Acequia Capital, Charlie Songhurst, Taavet Hinrikus, and Sten Tamviki, the company was off to a strong start. It joined forces with Carbocycle, the Columbia University spin-off, to produce and scale microbial lipids that would offer an alternative to vegetable oils and fats, made from organic waste.

In April 2023, after only two years of operations, Insempra introduced the first fermentation-based functional ingredient for consumer goods by signing a supply agreement with Axxence Aromatics for its 100% natural alpha-Ionone flavor. The aroma compound is found in natural sources such as raspberries, blackberries, and almonds. Originally developed by Phytowelt Green Technologies GmbH, Insempra refined said compound, stripping it down to the (R)-alpha-Ionone enantiomer, resulting in a deep raspberry and violet aroma, which can be used for flavoring and in fragrances. The ingredient is EU-natural certified, food-grade, and vegan. By contrast, to create a raspberry aroma by traditional farming methods would require over a hundred tons of the fruit and 40 football fields’ worth of cultivated acreage.

In May 2023, the enterprise announced a working partnership with fibers365 on the development and scaling of sustainable second-generation feedstock to fuel the commercial production of fermentation-based ingredients. By applying its fermentation technology platform to agricultural waste side streams, Insempra is able to develop specialty lipids for application in personal care, beauty, food, and nutraceuticals industries.

In November 2023, Insempra won €1.5 million ($1.6 million) in funding from The Federal Agency for Disruptive Innovation for its Bio Treasure prototype, an end-to-end bioproduction process that utilizes carbonaceous waste streams for new product creations and feeding microbes.

OxiProteomics

Founded in 2013 with initial funding by science and technology incubator Agoranov, OxiProteomics’ innovation is focused on protein oxidation (carbonylation), the irreversible protein modification that results in the decreased functional and structural protein quality associated with aging. The company’s patented technology detects functional versus damaged proteins in lab samples, assessing thousands of samples in one assay.

In skincare applications, that knowledge can assist in determining a healthy versus impaired skin function, reading factors of exposome stress such as UVA rays and pollution but also overall skin health. This knowledge can be applied for in-vitro, ex-vivo, in-vivo, and expression proteomics studies of products but also singular active ingredients. In hair and nail product trials, this level of research would be applied to keratin modifications in ex-vivo, in-vivo, and in-vitro studies. By measuring the stress on the hair follicle, the test provides an efficacy score of protection.

Curie Co

Founded in 2017 by Erika Milczek, Curie Co aims to replace petrochemicals with biopolymers and enzymes in microbial systems using cell-free protein synthesis. Thanks to its rapid product process, the company hopes to offer wider access to new enzymes in the personal care market. Milczek was inspired to create the company upon recognizing the smell of formaldehyde while getting a Brazilian blowout treatment.

The mission began with antimicrobial chemicals, with Curie Co engineering biodegradable, biocidal enzymes, called CuraVia, to offer a new alternative for preservative ingredients such as parabens in water-soluble formulas.

In 2018, it was selected as one of three skincare innovators in residence for Johnson & Johnsons' JLABS incubator and as a Sephora Accelerate cohort, as well as receiving funding from The Thiel Foundation’s Breakout Labs.

Biofabricate 2024 served as the platform to showcase its new product, Curamina, a bioactive binder for dermatological proteins that mimics the functions of the skin’s own enzymes. “Our mission is to use nature's playbook to replace petrochemical-based ingredients in everyday products with worry-free biobased alternatives,” Brittany Solano, Vice President, tells BeautyMatter. “Curamina is a sustainable, naturally derived bioactive that can form new peptide bonds to collagen and keratin without the health concerns of chemical exposure associated with aldehyde-based products.” The ingredient is 99% biobased and biodegradable, with applications in facial care, body care, smoothing treatments, and more. Benefits include UV protection, hair repair, and blue light protection.

Pitri

Pitri Ltd. is an early-stage startup disrupting the global colourants market, focusing on the power of pigments extracted from fungi to reduce humans’ dependence on non-renewable resources (namely minerals and fossil fuels) for colour. Pitri is developing a unique range of biofabricated colourants with an initial focus on beauty & cosmetics applications, and future ambitions in food & beverages, textiles, inks, paints, & coatings, and beyond.

Pitri is a spin out of designer & biomolecular scientist Jesse Adler’s graduate thesis research on the MA Material Futures course at Central Saint Martins, a proof-of-concept collection called Alchemical Mycology. Using different species of fungi, Adler is able to extract vibrant hues ranging from blood red to cyan blue, which are non-toxic, biodegradable, and high-performing.

By collaborating with fungi, Pitri challenges humans’ relationship with colour, valorizes fungi & their chemical extracts, and supports the transition towards more sustainable colouration practices across the beauty and cosmetics industries.

Melwear

Determined to offer an alternative to pre-existing UV protectants, Melwear offers a biocompatible and biodegradable alternative in the form of bacterial melanin. A higher presence of melanin has shown to offer natural UVR filtering and photoprotection qualities, thanks to the melanocytes (the cells that produce melanin) in the epidermis. With global melanoma rates expected to grow by 50% by 2040 and increasing debates around sunscreen safety—be it on an environmental or personal health level—the market is certainly hungry for alternatives. Melwear proposes its protectant in three different concepts: a SPF-containing foundation, serum sunscreen, and hydrogel sun face patches.

The company was founded by Maca Barrera, a multidsicplinary designer and recent MA biodesign graduate from Central Saint Martins. The concept began as a second skin garment of encapsulated melanin which grows darker as the wear is exposed to UV rays, with support from the Making Lab team at the Francis Crick Institute.

Bioweg

Bioweg was founded in 2019 by Dr. Prateek Mahalwar and Srinivas Karuturi. The enterprise has created a patent-pending, zero-waste process combining molecular simulation, fermentation, and material science for its innovations, utilizing agricultural waste to help contribute towards a circular economy and a green chemistry approach. The company pre-processes complex carbohydrate ingredients like molasses and vegetable peels to ensure optimal microbial growth conditions. Finding the optimal strains to employ was the result of over 10,000 lab-scale experiments, not to mention genetically engineering the strains in question.

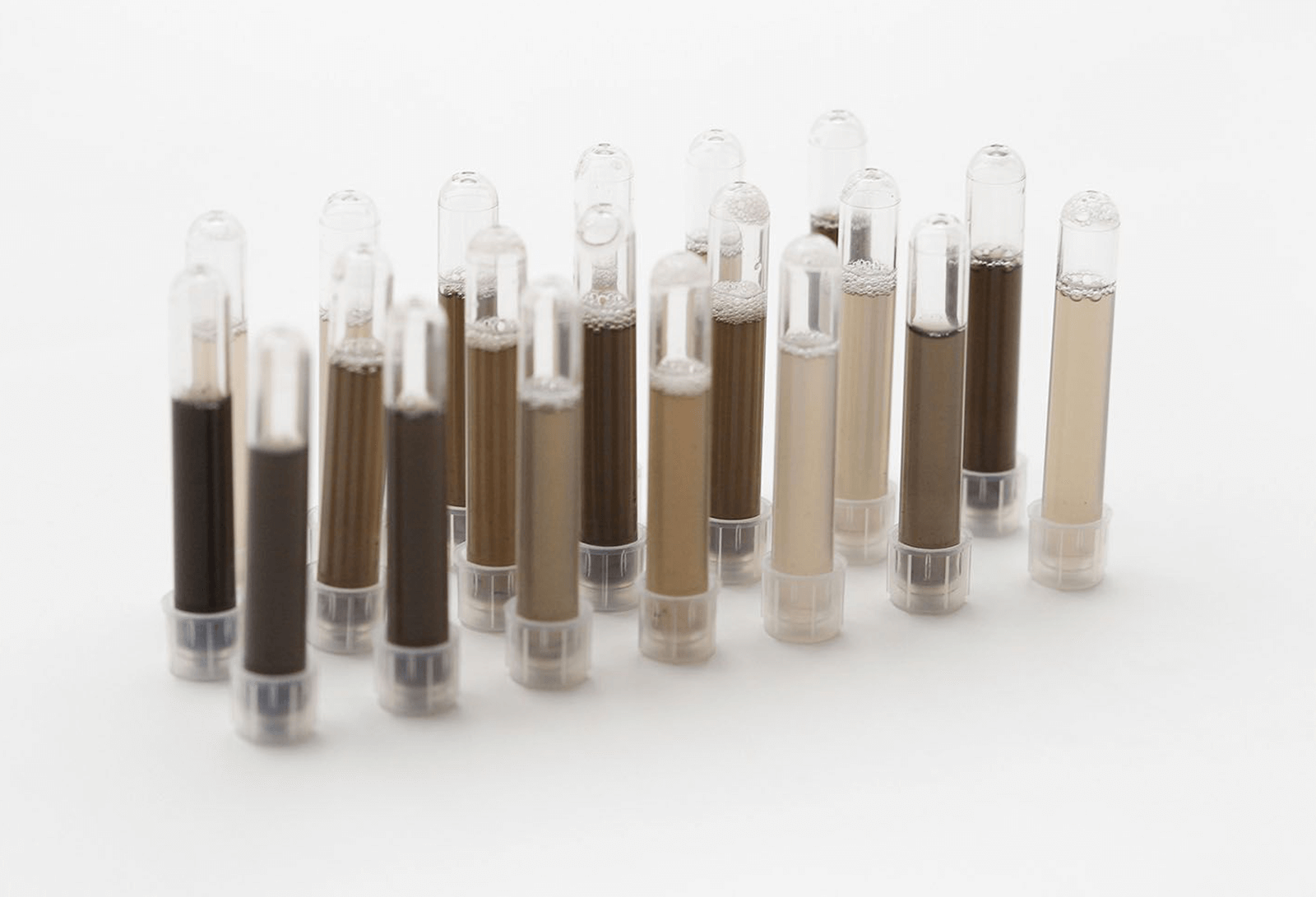

Cosmetic ingredients include MicBeads—biobased and biodegradable micropowder made using natural fermentation to replace microplastics polymethyl methacrylate (PMMA), Nylon 6, Nylon 12—and RheoWeg, a biodegradable rheology modifier to replace acrylic polymers; both ingredients are made using microbial microcellulose.

The company was recognized as one of the top three sustainability start-ups at LVMH Innovation Award 2023. In February of that same year, Bioweg announced a partnership with Gingko Bioworks to enhance the production of bacterial cellulose in order to ensure a wider adoption of thse ingredients to replace microplastics in the industry.

Mango Materials

Founded by Molly Morse, Allison Pieja, and Anne Schauer-Gimenez, the seeds for Mango Materials were planted when Morse and Pieja investigated the production of methane-derived polyhydroxyalkanoates (PHA) biopolymers as part of their PhD reseach at Stanford University. PHAs are microorganism-derived polyesters; in the case of Mango Materials, this ingredient is being used in pellet form, branded as YOPP and YOPP+—the former being the plant-derived version, the latter using methane. YOPP is an acronym for “You Oust Polluting Plastics.”

This biodegradable product can be used for packaging components like caps, jar, and bottles, as well as film and sheet applications. Mango Materials’ PHA is made using methane, for a one-two punch of plastic use reduction and utlizing greenhouse gas emissions for the better. The company partners with a range of enterprises to obtain its methane from landfills to wastewater treatment plants; it then employs methanotroph bacteria to produce PHA using said methane, resulting in a closed loop, low-cost, and highly scalable process. In a marine environment, the fibers of the material has been shown to biodegrade in roughly six weeks.

Sway

Sway has pioneered a responsibly sourced, seaweed-based, home compostable and durable plastic alternative. The company sources the ingredient from vetted ocean farms and processors in emerging blue economy zones and extracts the natural polymers of seaweed, which mimic the qualities of plastic. These polymers are blended with renewable sugars and starches before being transformed into packaging. Sway is also continuing to research into the environemntal and social impacts of seaweed farming, including on biodiversity, carbon sequestration, and water quality.

The company won the Tom Ford Plastic Innovation Prize in March 2023 and has raised over $7 million in its December 2023 seed funding round, with a previous undisclosed grant from Katapult.

Sparxell

Inspired by the structural colors of plants and animals, Sparxell uses cellulose nanocrystals in helix-like structures to deliver sparkling effects and shades without the microplastics. Founder Benjamin Droguet began the concept while working as a research associate at the University of Cambridge.

These biodegradable and renewable materials are sourced from agricultural by-products like wood pulp. The crystalline parts of the cellulose are extracted and prepped in water, with the crystals self- assembling into an ordered state upon drying, and then treated with Sparxell’s patented technology to form a light- and color-reflecting film. Controlling the interactions of the crystals determines the outcome, making the cellulose film highly customizable. Aside from use in color cosmetics to create vibrant eyeshadow hues and eye-catching glitter finishes, the company also offers an advanced range with UV- and IR-reflective properties.

Capra Biosciences

Capra Biosciences was co-founded by Elizabeth Onderko and Andrew Magyar and emerged from SOSV’s IndieBio program. In June 2022, the company announced a $1.8 million pre-seed round with investors including Prithvi Ventures, the E14 Fund, and GS Futures.

The company’s first product is a bio-built retinol, fueled by the bioreactor technology invented by Onderko while studying as a postdoctoral associate at the U.S. Naval Research Laboratory. The technology (ideal for creating hydrophobic molecules) uses the biofilm-forming bacteria found in marine environments to create specialty chemicals, thanks to the direct solvent extraction and continous product synthesis enabled through the bioreactor. Aside from reducing greenhouse gas emissions and offering a more sustainably sourced alternative, Capra Bioscience’s model also offers a lower production cost thanks to affordable sourcing and co-localized manufacturing.

Cambrium

The Berlin-based start-up debuted NovaColl, a skin-identical, vegan, and mico-molecular collagen molecule in March 2023. In the category of Type I collagen (the fibrillar type and most abundant resource of collagen in the human body), the molecule was found by scanning billions of collagen sequences and selected for its efficacy and biocompatibility because the molecule is 100% skin-identical. The ingredient is grown through a yeast fermentation process, and due to its micro-molecular structure, demonstrates increased skin benefits. Cambrium was co-founded by Mitchell Duffy and Charlie Cotton in August 2020 and raised an €11 million ($11.8 million) seed funding round in October 2023.

Cellugy

EcoFLEXY is a fermentation- and cellulose-based ingredient made using sucrose. A specific strain of microorganism converts the sucrose into biocellulose, which is completely biodegradable. Potential for applications lies in personal care products, specifically in thickening formulations. Cellugy highlights that the fermentation process it uses offers an inexpensive, less resource-intensive alternative to other forms of cellulose production.

The company launched in 2018 and was co-founded by Isabel Alvarez-Martos, Deby Fapyane, and Parun Sihombing. In January 2021, the enterprise received over 17 million DKK ($2.4 million) as part of the EIC Accelerator program.